SMCore is innovating the manufacturing paradigm through Smart Factory.

We

provide specialized Total Smart Machine Solution.

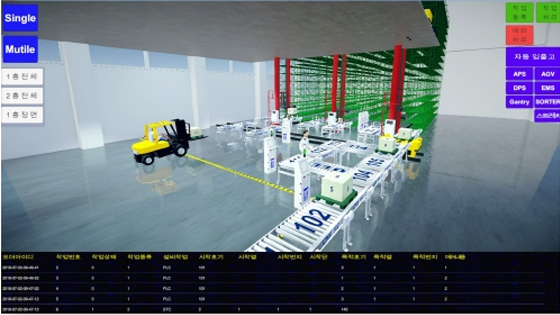

Logistics System

The range of logistics automation businesses is varied and automates and optimizes the entire logistics process by providing efficiency,

speed and reliability from automation of material flows to classification, picking and storage processes.

-

Warehouse Automation

Warehouse AutomationASRS(Automated Storage and Retrieval System) Automated Storage and Retrieval System (AS/RS) is an optimal solution to manageits inventory against the specific but diversified needs of customers in various industries.With more than 70 years of history, SMC became an expert handling extremely high volume throughput and large numbers of SKUs in AS/RS. AS/RS generally consists of machines that move up and down in one or multiple parallel storage aisles. Our proven technology iscapable of effectively and reliably handling and buffering raw materials, work-in-process inventories and all kind of finished goods.SMC can make total integration of material handling and storing possible.

-

Process Automation

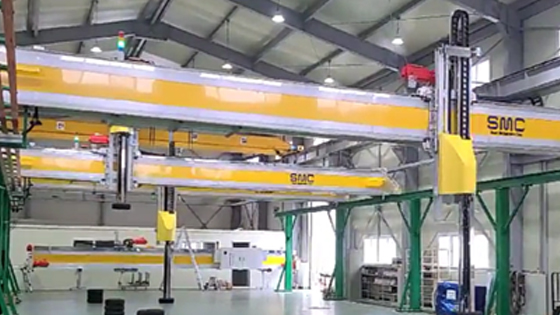

Process AutomationOne of the most important applications of automation technology is process. Also, the process automation system improves process efficiency and utilizes various conveyors to maximize transportation effeiciency. Especially in the manufacturing process, careful processing of high-quality raw materials and parts management are important. Robotic transport such as Gantry Robot, EMS and SMCore's WMS control system carry the product to the desired line at the right timing. It Increases process flexibility to cope with various handling types, improve product quality through real-time inventory management and intelligent management of logistics.

Category

-

Forming Rack / Welding Rack

It is a steel structure that stores the most basic cargo in the automated warehouse area. There are Rack Supported Building(RSB) type which is a warehouse building when a rack and a steel frame of a building are made up together and wall and a roof are added and FSR(Free Standing Rack) type which is additionally installed when the building is completed.

Stacker Crane

Stacker crane takes the main role in automated storage and retrieval system (AS/RS) as performing loads transit.Stacker crane travels along the aisle and transfer loads from a specific storage location to an input or output station and vice versa. SMC’s Stacker Cranes’ millimeter precise positioning, forking, and centering allow users toconfigure easily with flexibility for almost any application.

-

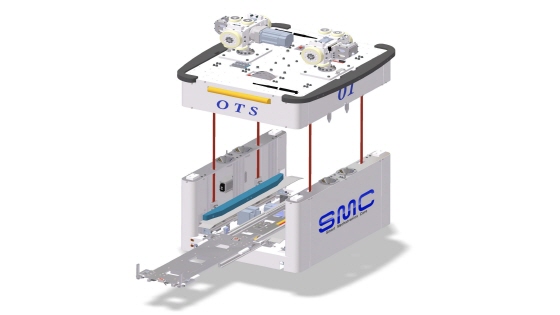

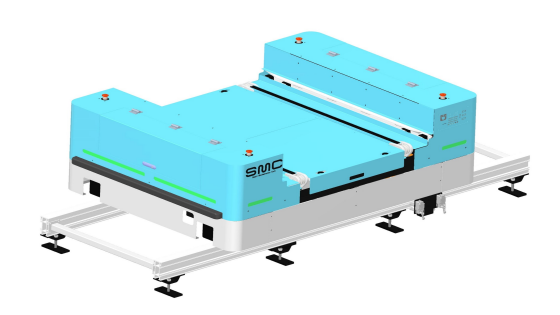

OTS(Overhead Traveling Shuttle)

OTS is a device that can perform curved driving and move freely between racks by changing direction on its own. Since it is installed on the ceiling, it has a high space utilization rate, and allows for quick transportation and transfer of cargo by enabling the shortest distance transportation.

Pallet Shuttle / Runner

Pallet Shuttle/Runner is a device that helps with the loading and transportation of cargo independently within a racking system. It can be operated in various forms depending on the water volume, space, and operation method, and its biggest advantage is maximizing the product loading space while handling the largest amount of water. The design varies depending on the characteristics of the transported cargo according to customer requests.

-

Conveyor

Conveyor is the most common and basic automated material handling equipment which transfers loads from one location to another in economic and simple way.SMC offers an optimized conveyor systems to transport, accumulate, reorient, or stage loads, which reduce all the inefficient factor in typical working process. Type : Chain, belt, roller, spiral, free flow, 180 degree turning conveyor, etc.

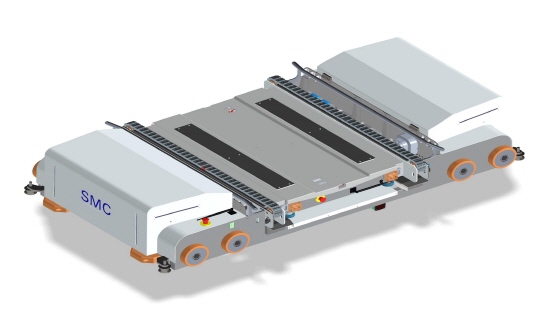

RGV(Rail Guided Vehicle)

Rail Guided Vehicle is a fast and flexible material transporting system with separate input/outputstations that allow RGV to perform multiple performances at once. SMC offers linear andloop types of RGVs, which runs safely and smoothly at high speed, to provide maximized performance for customer’s needs.

-

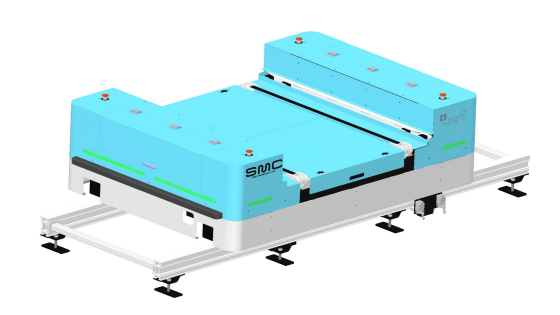

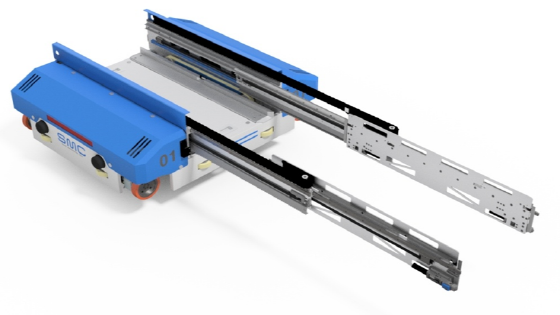

4Way R Shuttle

4Way R Shuttle is a device that can move freely between racks by changing direction (in 4 directions) through the rotation of its wheels. It has a lightweight structure and various driving systems can be applied to maximize product loading space, enabling efficient cargo loading and transportation.