SMCore is innovating the manufacturing paradigm through Smart Factory.

We

provide specialized Total Smart Machine Solution.

Logistics System

The range of logistics automation businesses is varied and automates and optimizes the entire logistics process by providing efficiency,

speed and reliability from automation of material flows to classification, picking and storage processes.

-

Process Automation

Process AutomationOne of the most important applications of automation technology is process. Also, the process automation system improves process efficiency and utilizes various conveyors to maximize transportation effeiciency. Especially in the manufacturing process, careful processing of high-quality raw materials and parts management are important. Robotic transport such as Gantry Robot, EMS and SMCore's WMS control system carry the product to the desired line at the right timing. It Increases process flexibility to cope with various handling types, improve product quality through real-time inventory management and intelligent management of logistics.

-

Warehouse Automation

Warehouse AutomationASRS(Automated Storage and Retrieval System) Automated Storage and Retrieval System (AS/RS) is an optimal solution to manageits inventory against the specific but diversified needs of customers in various industries.With more than 70 years of history, SMC became an expert handling extremely high volume throughput and large numbers of SKUs in AS/RS. AS/RS generally consists of machines that move up and down in one or multiple parallel storage aisles. Our proven technology iscapable of effectively and reliably handling and buffering raw materials, work-in-process inventories and all kind of finished goods.SMC can make total integration of material handling and storing possible.

Category

-

Conveyor

Conveyor is the most common and basic automated material handling equipment which transfers loads from one location to another in economic and simple way.SMC offers an optimized conveyor systems to transport, accumulate, reorient, or stage loads, which reduce all the inefficient factor in typical working process.

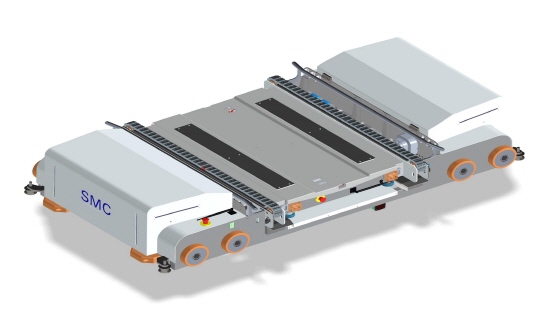

Type : Chain, belt, roller, spiral, free flow, 180 degree turning conveyor, etc.RGV(Rail Guided Vehicle)

Rail Guided Vehicle is a fast and flexible material transporting system with separate input/outputstations that allow RGV to perform multiple performances at once. SMC offers linear andloop types of RGVs, which runs safely and smoothly at high speed, to provide maximized performance for customer’s needs.

-

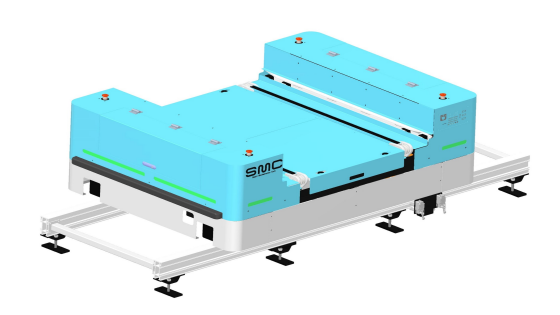

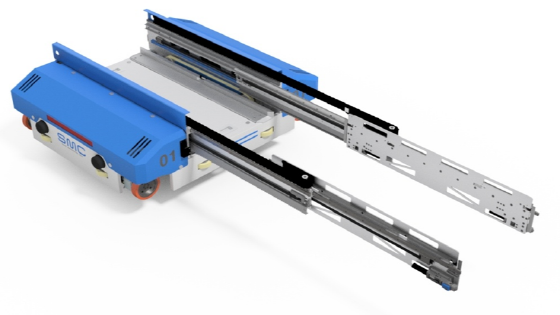

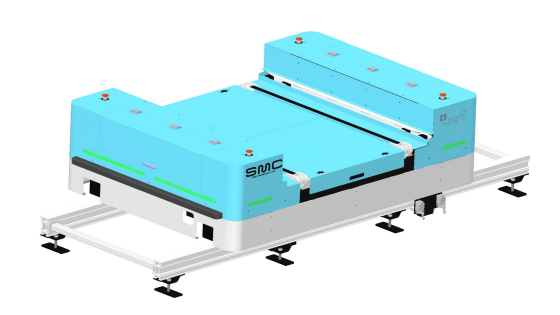

AGV(Automated Guided Vehicle)

SMC designs and manufactures an innovative Automatic Guided Vehicle (AGV) system,which has flexible and advanced navigation systems and provides a reliable performance in automated material movement.

LGV(Laser Guided Vehicle)

SMC manufactures Laser Guided Vehicle (LGV) operated by LGV controller,which communicate data via laser frequency and travels on predictive route. Hence,LGV does not need any rail, guide tape attachment or visible guidance to find it’s destination.

-

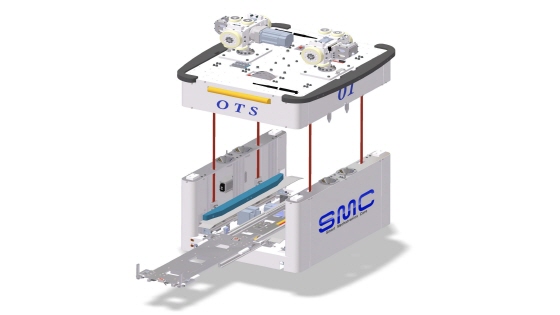

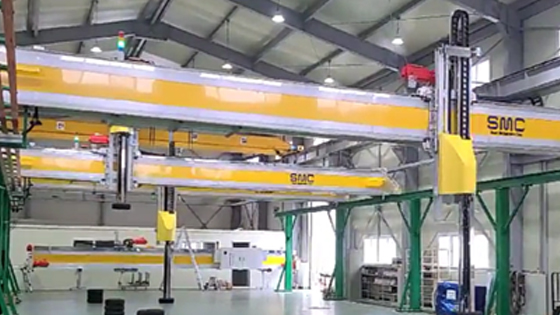

Gantry Robot

SMR-10 consists of a manipulator mounted onto an overhead system that allows movement across a Horizontal plane.Its servo motor operates gantry robot, alike overhead crane which moves in X, Y, Z axis with full speed of approximately240m/min, and maximizes throughput from point A to B. Moreover, SMR 10 is capable of loading and unloading cohesive designated area under immaculate control. New generation SMR-20 is built with light and simple bridge to give more benefit for installation.Its flexible design of beam also allow easy adjustment of installation.

EMS(Electric Monorail System)

Electronic Monorail System (EMS) is an overhead type rail guided vehicle which therefore save spaceand provide high performance in a beeline. Each carrier can be designed into cage, conveyor, or chuck type according to customer’s requirement,and deliver products safely by accurate position control.Transportation and distribution of a variety of items/products can be executed simultaneously. SMC’s EMS ensures stable loading/unloading As wire goes up and down and transfers to the designated destination, which can be applied to any circumstances.

-

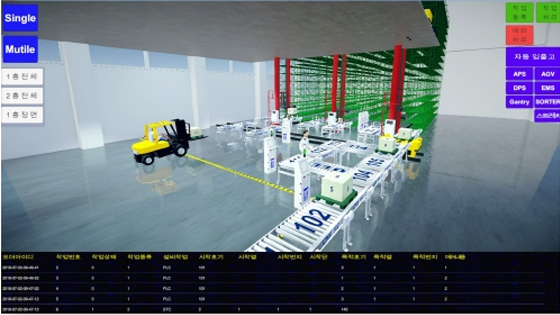

WMS(Warehouse Management System)

WMS is a system that implements in-house/out-of-house supply chain management processes that are responsible for logistics flows in the warehouse from warehousing to delivery, and improves accuracy and productivity in the warehouse by performing warehousing, storage, and forwarding functions.